Tariffs aren’t just headlines—they’re one of the reasons international costs can be tough to predict. Shipping rates swing, duties shift, and even small changes can ripple throughout margins.

Most teams can adapt when they have to, but there’s a smarter way to get ahead of the volatility: look stateside and switch to a US-based packaging supplier.

1. Stable pricing and lower shipping costs

Working with a U.S.-based packaging supplier provides clearer pricing and far fewer surprises. Instead of juggling international add-ons like customs, duties, storage, and fuel surcharges, it’s typically a far more straightforward cost structure with tariff-free packaging that’s easier to plan around.

With tariffs continuing to influence the price of imported materials—some rising 10–40% according to MJBizDaily—domestic partnerships offer a steadier, more predictable path forward.

Plus, shorter shipping distances naturally reduce transportation costs. And with access to reliable ground and air freight, U.S. suppliers make it simpler to hit timelines and keep budgets on track.

In short, choosing domestic isn’t just about avoiding volatility. It’s about gaining consistency, control, and a supply chain that supports long-term growth.

2. Faster lead times

Distance isn’t the only factor that shapes fulfillment speeds. But it is a major reason why many teams are taking a closer look at domestic options.

Recent fluctuations in international freight have shown how quickly pricing and timelines can shift, with U.S.–bound shipments from key regions dropping nearly 30% in a single week and major ports experiencing more blank sailings and offshore holds.

These kinds of swings can make planning harder than it needs to be. A delay overseas can ripple into launch timelines, inventory management, and forecasting.

Domestic partnerships, on the other hand, naturally offer shorter, more predictable lead times—and without the layers of geopolitical or port-related variables that come with long-haul imports.

While no supplier is completely immune to delays, choosing a reputable U.S.-based partner provides a more stable, consistent fulfillment experience and far fewer surprises.

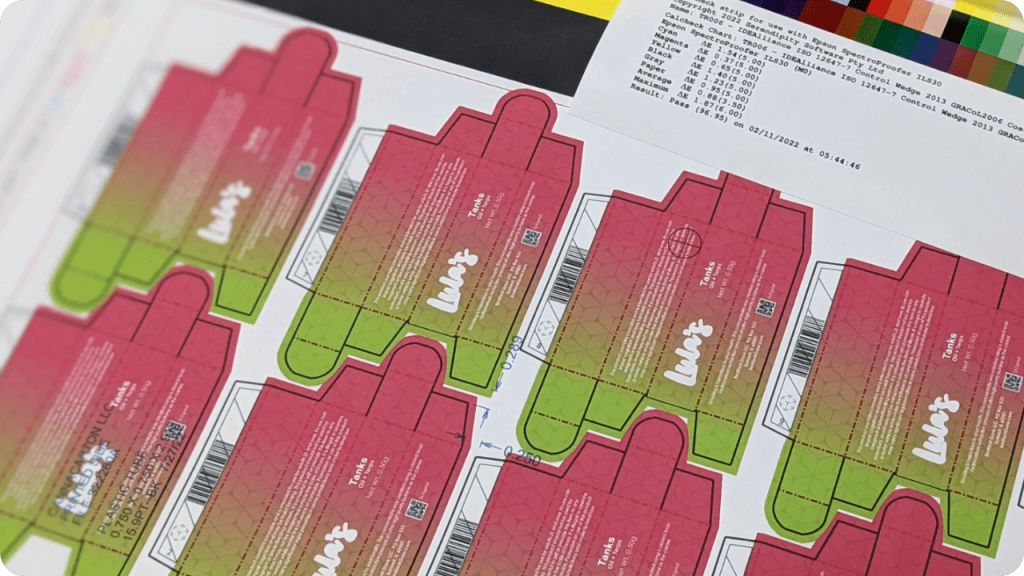

3. Guaranteed quality and consistency

U.S.-made products come with a level of consistency and craftsmanship that’s hard to beat. While pricing can vary, the quality and reliability of domestic production often deliver greater long-term value.

Part of that confidence comes from the standards these facilities operate under. Many follow strict guidelines like GMP, ISO, and SQF Level 3, with regular audits to ensure processes stay clean, controlled, and transparent. Companies always know what they’re getting—and why it performs the way it does.

Working stateside also means easier access to physical samples, more precise color matching, and smoother communication throughout the project. Some manufacturers—including us—welcome in-person visits, giving a firsthand look at the production floor.

Ultimately, it’s about more than quality. It’s about having a partner who delivers the right result every single time.

4. Reliable and resilient supply chains

International suppliers can do great work, but they’re naturally limited by customs processes and longer transit routes.

Even with solid redundancies in place, it’s harder for them to pivot quickly when something changes. Diverting shipments or sending replacements often takes more time, coordination, and cost than most teams want to absorb.

U.S.-based suppliers offer far more flexibility by comparison.

With multiple facilities, regional partners, and a wider range of shipping options, they can adjust quickly if a route slows down or inventory gets tight. That kind of built-in adaptability helps keep schedules intact and projects moving.

Suppliers are also better insulated from global economic swings, material shortages, or customs-related delays. And depending on location, options like regional delivery or local pickup can make things even easier.

Now, we’ll be honest, getting things made in the U.S. will probably always be more expensive. But American manufacturers are working hard to stay competitive, especially in an industry that’s been very open to sourcing from overseas.

The real payoff is a steadier experience and a supply chain that can be relied on.

5. Higher level of customization

U.S.-based suppliers offer a broader level of flexibility across both design and packaging formats. Brands can work with a wider selection of materials, sizes, and finishes instead of being limited to standardized templates.

When a domestic partner also houses an in-house design team, the entire process becomes even more streamlined. There’s no need for fully finalized branding or complex file preparation before beginning. The collaboration stays aligned from concept through production, minimizing delays and ensuring accuracy at every step.

This approach allows teams to review samples, make real-time adjustments, and confirm every detail before full production. The result is custom packaging that feels intentional, reflects the brand, and stands out on the shelf.

And looking across the industry, the brands that consistently build strong connections with consumers tend to be the ones that use their packaging exceptionally well.

Domestic suppliers are uniquely positioned to support that level of creative and strategic alignment—from design through delivery.

6. Lower minimums

Cost advantages from international suppliers often depend on buying in large volumes.

Per-unit prices may drop, but the total spend increases. And those bigger commitments can create challenges when demand shifts or a design doesn’t land as expected.

Local manufacturers typically make lower-volume ordering far more feasible. That flexibility supports small-batch launches, design refinements, and product testing without stretching budgets or locking capital into long-term inventory.

As packaging trends evolve and material costs shift—glass being a recent example—having the ability to explore alternatives like pouches or cartons becomes increasingly valuable.

Smaller minimums make it easier to adapt, experiment, and stay aligned with changing consumer preferences without taking on oversized or uncertain commitments.

7. Local contacts

Customer service takes on a different level of quality when the partnership is domestic. Communication moves faster, responses are clearer, and there’s direct access to the team actually managing the account.

With the right supplier, the support experience feels genuinely personal.

Instead of tickets or automated forms, conversations happen in real time with people who understand the project and its goals. That kind of hands-on involvement makes it easier to resolve issues, adjust details along the way, and maintain alignment from first concept through final delivery.

8. Greater understanding of legal requirements

State-by-state packaging laws shift often, and keeping up with those changes can be challenging. A knowledgeable U.S.-based supplier brings awareness of regional requirements and can help teams stay ahead of updates before they impact production.

While packaging partners aren’t a replacement for legal counsel, the right one can highlight common compliance considerations and steer projects toward safer, more reliable options.

From child-resistant standards to warning labels and layout guidelines, this kind of guidance helps prevent missteps, maintain compliance, and keep products moving smoothly through the supply chain.

9. Everything in one place

Many cannabis producers work with multiple vendors for sourcing, design, printing, and fulfillment simply because that’s how they’ve always done it. But managing several partners adds layers of coordination and can introduce unnecessary friction across the workflow.

A well-equipped domestic partner streamlines the entire process by offering a true turnkey solution.

With everything handled in one place—from early concepts to final delivery—projects move faster, communication stays aligned, and branding can be applied consistently across nearly any packaging format.

Not every U.S.-based supplier offers this level of end-to-end capability, so selecting a partner with proven expertise across the full production process makes all the difference in achieving a smooth, unified experience.

10. Eco-friendly and sustainable

Sustainability isn’t limited to the materials used in packaging. The environmental impact also ties into how products are produced, printed, and shipped.

A strong U.S.-based partner can provide a range of sustainable packaging options—such as ocean-recycled plastic and FSC- or SFI-certified paperboard—while maintaining cleaner, more efficient practices throughout their supply chain.

Local manufacturing further supports these efforts through lower freight emissions, better oversight of energy use, and reduced waste across the production process. While these improvements can come at a higher cost, many brands find the long-term benefits well worth the investment.

If sustainability is a core value—or a clear customer expectation—choosing a responsible packaging approach sends a meaningful signal. And a local manufacturer is often best positioned to support those commitments with transparency, consistency, and measurable impact.

Customize with CannaCarton

Looking for packaging that’s reliable, compliant, and designed to stand out?

CannaCarton delivers custom cannabis packaging with fast lead times, strong quality control, and sustainability woven into the process.

As a U.S-based, minority-owned manufacturer, the team supports every stage from concept to shelf with a hands-on, collaborative approach. The result is packaging that reflects the brand and performs the way it should.

Connect with our team to explore options or request a custom quote.